King Games

August 20, 2022

Largest Us Cities

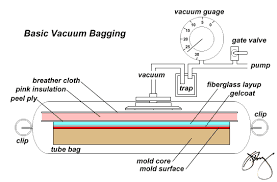

August 22, 2022The first step in vacuum bagging is making sure that you’ve got a good seal around the bag. This is especially important around the vacuum coupler, which is the point where the vacuum line attaches to the bag. If you’re unsure of the seal around the vacuum coupler, consider hiring someone to help. In this article, you’ll learn what a good seal means and how to create one. By the time you’re done reading this, you’ll be well-equipped to vacuum bag efficiently.

Pleats

Thermoplastic elastomer films can withstand vacuum bagging operations without failure. These films are available as block copolymers or a blend of polymers. Thermoplastic elastomer films are especially preferred over a blend because of their flexibility and the ability to conform to the laminate during debulking. This material also works well with reduced pleats. However, it is not as effective as a rubber-like material.

Vacuum bags with pleats are generally better than those without, as the film will conform around the part evenly and create consistent vacuum pressure. The shape and size of the part will determine what kind of bagging film is used. This will help you achieve bagging success. A few tips to keep in mind when choosing a vacuum bag:

Vinyl

Polyurethane and vinyl vacuum bags are two commonly used materials. The former is much more flexible and durable, and the latter is more pliable. Both are used for different purposes, from removing dust from a car to cleaning woodworking tools. Polyurethane bags are generally 30 mils thick, while vinyl vacuum bags are usually only 27-30 mil thick. Vinyl bags are a good choice for occasional woodworking, but they are not as flexible or durable as polyurethane.

Polyurethane

Extruded polyurethane is a water-clear material used in vacuum bagging. Its high puncture resistance, good elasticity, memory retention, and moderate temperature resistance make it an ideal choice for vacuum bagging. Typical high-volume applications include large components and moulds. Global offers high-volume polyurethane membranes that can be up to 3200 mm wide. These high-volume vacuum bagging membranes can be used in both high-tech and general shop applications.

Polyurethane vacuum bags are designed for vacuum bagging in multiple applications. For example, they are used in resin infusion, prepreg processing, hand layup, filament winding, and compression moulding of thermoplastic composites. They are flexible and tough, with double-end entries and C channel closures. The double-ended design allows for smaller setups and faster pressing times. However, polyurethane vacuum bags are not suitable for use in vacuum presses without a pump.